Система слежения TH6i

Заказать звонок

The eyes of the robot ...

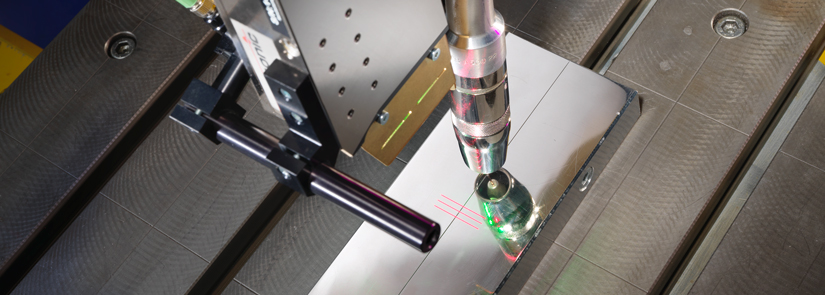

The seam tracking sensor TH6i equipped with a second greyscale camera system is a product solution with outstanding seam tracking performance, especially for butt weld applications and highly reflective materials. TH6i is the only sensor that manages gap detection from 0.02 mm even with reflective surfaces.

The in-process optical seam tracking with TH6i paves the way towards a perfect welding seam especially at butt weld applications with narrow joint gaps that are hardly visible to the human eye. Components and minimal joints are recorded using a combination of laser lines, camera, additional greyscale camera system and green light allowing the course of the welding seam to be corrected in real time. Contact free and independent of both system and process, the method is suitable for all standard seam shapes and types of material.

Top-level jointing technology ...

The only way to do justice to increasing requirements in the joining technology, continue to work efficiently and remain competitive is to use state-of-the-art product and process solutions especially in the fields of sensor technology.

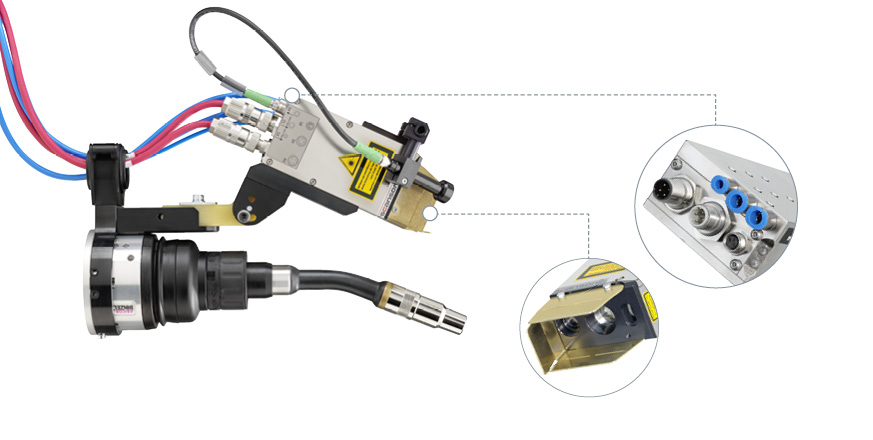

New developments and perfectly coordinated system solutions – like the optical seam tracking sensor TH6i and the comprehensive ABICOR BINZEL ROBOTIC SYSTEMS product range – contribute towards improving automated processes.

Precise and insensitive all-rounder ...

The optical seam tracking sensor TH6i is an innovative system solution for versatile applications in the field of automated welding. Typical examples of TH6i applications can be found in pipe and container construction. It has a very sturdy design and guarantees smooth operation even very close to the process thanks to the integrated incident light filter. The high-performance signal evaluation ensures reliable seam guiding. Particularly on reflective surfaces.

System Overview:

Advantages that speak for themselves:

Precise

- Gap detection from 0.02 mm

- Exact identification of the seam position and determination of the alignment of the sensor head to the seam thanks to the use of the three-line laser

- Above-average process reliability even with demanding seam tracking

- High measuring data recording stability

- Corrections in real time

Insensitive

- Splatter protection with integrated air flushing of the protective glass and air cooling of the sensor

- Splashwater-proof housing

- Optical filter to prevent falsified measuring results

- Resistant to faults caused by electric fields

All-rounder

- Suitable for all standard seam shapes

- Suitable for all standard surfaces, particularly reflective and high-gloss ones such as aluminium or stainless steel

- Interfaces to well-known robot controls available

- Standardized interfaces analog and digital available

| Measuring lines: | 3 |

| Working distance: |

150 ± 12 mm |

| Field of view (WxH): | 16 x 24 mm |

| Resolution (WxH): | 0.03 x 0.07 mm |

| Measuring rate: | 60 Hz |

| Dimensions (WxHxD): | 70 x 40 x 140 mm |

| Operating temperature: | 10ºC up to 45ºC |